100% Pure Maple Syrup. An old Lasley Tradition

Corey's' paternal ancestry traces back into the Odawa and Ojibwe (Chippewa) tribes of northern Michigan, in which the practice of maple sugaring was passed down from parent to child for generations. Making what the Ojibwe called anishinaabe-zhiiwaagamizigan, that is, maple syrup; Corey's grandfather George Lasley learned from his father Henry likely at a very young age, and became an expert at the craft. George annually tapped many sugar maple trees on his 40 acre woodlot and elsewhere in the vicinity of Cross Village, Michigan.

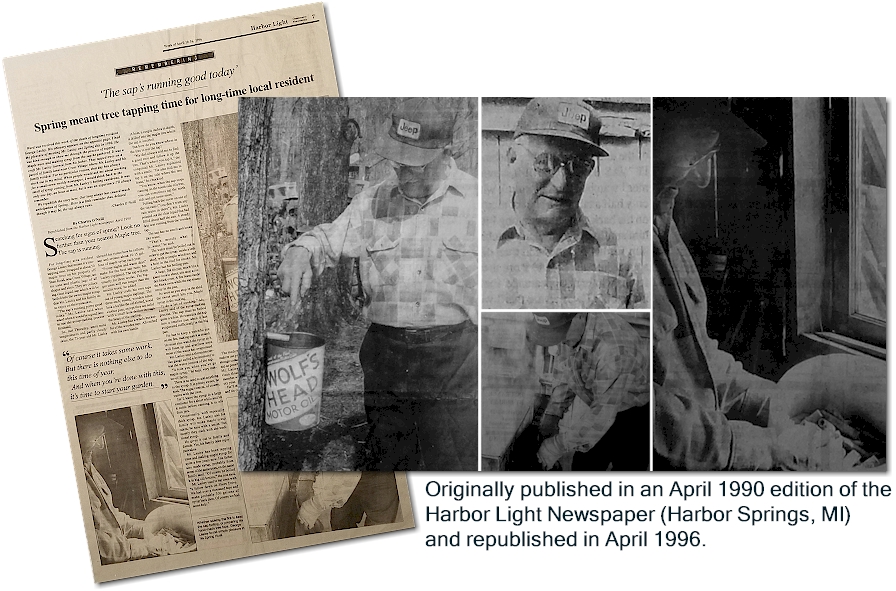

Whereas George’s father’s boiling operation was more traditional, through the use of kettles over a fire, George’s operation was likely a bit larger, though still very makeshift and thrifty. His taps were hand crafted from wood, and his collection buckets were actually old motor oil cans (well cleaned of course). He eventually upgraded his operation around 1964, and built the “sap house” which was a small shack of rough sawn lumber and straight tree trunks/branches for beams, a concrete floor, and a metal roof he could prop open on one side to let out the steam. His boiler was made of cinder blocks that held up a large metal home-fabricated pans that could boil a large amount of sap over the heat of burning wood. In his prime, and working with some help, he had at least one season where he ran 1000 taps, resulting in 300 gallons of syrup.

George was well known in Cross Village for his maple syrup. By the time I came around, Grandpa would drive his late 70's model Jeep CJ down the old logging trails on the property with a large metal drum. He would collect the cans that had a good amount of sap, walk them down to the Jeep and empty the contents of the can into the drum through a cloth stretched over it’s opening to filter out any bugs and/or debris.

George made maple syrup until his last full year of life, though his operation diminished over the years as it became increasingly more difficult to navigate the wooded terrain. He passed away in the winter of 1996, and thus ended the family tradition. The property is still owned by his children, and the ramshackle old sap house still stands to this day. To see more of my Grandpa's old sap house, checkout a short video on my YouTube channel called: My Grandfather's Old Sap House / Sugar Shack (Making Maple Syrup)

A Tradition Rekindled 850 Miles South

Though the tradition faded with my Grandfather in the early 1990's, Corey was determined to get the fires of the sap boiler going once again; though Corey was under the assumption it would be much later in life, when he would have enough free time to spend a few weeks up north on the old Lasley homestead (i.e. retirement.) However, having moved our family to the Blue Ridge Mountains of North Carolina at the tail end of 2018, we were able to make our home on a small property in Zionville loaded with a number of mature sugar maple trees, 30 of them in fact. In the winter of 2020, Corey would officially light the fires of a makeshift sap boiler...

Get the latest updates on the 2024 Season

Corey's Logs: The 2020 Season

The 2020 maple sugaring season was fairly successful considering that it was my first run. Despite having about 30 mature sugar maple trees on my 1.5 acre lot, because this was my first go at this, I had only 8 taps running. The season caught me a bit off guard, as I was thinking in terms of Michigan’s typical season, which, if memory served me correctly was typically in later March, even as late as early April. 2020 maple sugar season in North Carolina however started here at the tail end of January.

A week before the weather

conditions were perfect for sap flow (temperatures down in the 20s at night, and up into the 40s during the day,) I slapped together a makeshift boiler with scrap parts I

had laying around (including the frame of an old treadmill, and a oval galvanized steel tank. I had to buy the black pipe and elbow.) After collecting my first 15-20 gallons of sap, I began boiling using one of my Grandfather’s old smaller pans. Unfortunately the pan had a tiny leak along a weld that had gone bad, and I lost an

unknown amount of sap. To boil down this first batch of sap took about 12 hours, from the time I fired up the boiler around noon, and it was close to midnight before I was

finishing the job. I was only able to do this about 5 times, before the sap stopped running. I learned many lessons, had to buy a new boiler pan, and by the end of the season, which only lasted a few weeks, I produced less than a gallon of syrup.

It was a fun experience, and a LOT of work. Now that I know that I can actually do this, I plan to up my production attempt for the 2021 season.

Corey's Logs: The 2021 Season

Season began on January 12th, as the temps looked prime for good sap flow. I tapped 14 trees, and the next evening collected 13 gallons of sap. The next evening I collected about 34 gallons, and on the 3rd evening, another 25 gallons. I performed my first boiling of the season that Saturday, and boiled all the sap down to close to finishing concentration in about 12 hours. On Sunday, I spent about 4 hours finishing, and ended up with a little more than 1 gallon of syrup.

The 2021 season has been HUGELY productive, but also very tiring. The reason for this is that my makeshift boiler is terribly inefficient. To boil down 80 gallons of sap has been taking 17-20 hours, and a considerable amount of firewood. Though I am not actively tending to the boiling process for all of that time, I do have to keep the fire hot, and pour more sap in the boiler as evaporation occurs, so I cannot walk away for too long. I am learning a few things that I will have to implement for next season.

By the first week of February, I had nearly exhausted my firewood supply, and the sap was continuing to flow just as good as ever before. Having reached nearly 350 gallons collected over the course of the prior several weeks on just 15 taps, I was overrun with what I had the capacity to process. Because of extraordinary boiling time, and the fact I was burning through so much firewood, it was beginning to lose its fun. With as much as I absolutely hated to do it, my last sap collection on February 9, of over 20 gallons, had to be dumped. I didn't have enough firewood on hand to process it, and the temperatures outside were going to be too warm to hold on to it without risk of it spoiling until I could get my hands on more wood. At that, I called it a season. A great season, with a lot of syrup made, and a lot of lessons learned to help prep me for the 2022 season.

Lessons and Takeaways

My makeshift boiler is losing a lot of heat. With it being made from a galvanized steel tank, the walls are thin, and heat easily escapes the sides. I also do not have it sealed very well, as in I have a sheet of steel that I use to block heat escaping the largest open side of the pan (sine the pan doesn’t fit over the full width of the steel tank,) all the while there are various other large openings where heat is escaping around the pan. Additionally, I have left the area where I insert firewood, wide open. I didn’t realize that dampening this would encourage the flames to roll under the pan better. Additionally, I boil out in the open. Some days are cold and windy, and on such days, boiling takes considerably longer as the cold winds work to cool the pan.

I have noticed that even with extremely high heat under the pan, it really takes actual flames touching the pan to get a good rolling boil going. Additionally, I need a good way to preheat cold sap before adding it to the boiling pan. When the level of sap in the pan drops, I add more sap, usually several gallons, which then stops any good boil I have going.

Additional research has also led me to realize that the depth of sap that I have in a pan at any given time is far too deep, which is also having substantial impact on the time it takes to boil. The optimum depth of sap should actually be around 2”, where I have kept sap between 4”-6” deep. A 2” dept is difficult to maintain without a continuous flow setup, where a trickle of sap is constantly let into the pan, while the sap boils, maintaining a 2” depth.

Things to shoot for next season and beyond are the following:

- Harvest and season more firewood asap.

- Build a new boiler, made from cinder blocks filled with earth, to help prevent heat escaping.

- Build a “Sap House” / "Sugar Shack" around the boiler to prevent wind and rain/snow from interfering. I do have a large shed, that I could convert to this.

- Build a Reverse Osmosis pre-boil system (like this one,) to reduce the amount of boiling needed, which would probably cost between $300-$500 to build.

- Possibly invest in a continuous flow setup (i.e. something made by Smoky Lake Maple or Leader). This would likely cost $2500+.

Corey's Logs: The 2022 Season

The 2022 season was a season that provided more lessons learned, and despite slightly better preparation than the previous year,

the weather conditions helped lead to a smaller harvest than in 2021. Because of inconsistent consecutive periods of ideal temperature

shifts, we waited a week or two later to start tapping the trees than in previous years, which proved to be a mistake, as there is

little doubt we lost on some harvest opportunity because of this. Additionally, we didn’t invest in our maximum number of taps/tubes

that we could have, and we still had a number of trees that were left untapped this year.

Late 2021 and early 2022 was the year of investments for Lasley Rustics. At the tail end of 2021 we ordered an evaporator setup from

Smoky Lake Maple Products. We did not expect it to arrive in time for the 2022 season, but it actually did, and we were pleased that

we wouldn't have to go through another season with our highly inefficient homemade setup. The new evaporator certainly proved to be

more efficient, as we were able to boil more sap per hour than before, cutting the general boil down anywhere between 2/3 to 1/2 the

time I took with our makeshift evaporator setup. The finishing process still remained both time consuming and messy.

The manual labor of lugging full 5-gallon buckets of sap uphill with slushy snow on the ground much of this season was pretty

treacherous, though we managed to not have any accidents. The need for a sap house/sugar shack, and in a better location, seems to be

more and more necessary to ease the burden of collecting and transporting sap. Corey plans to build a little sap house, both downhill,

and more central to the sugar-bush.

The demand for our maple syrup was up from the previous year, so we sold out of it very fast. In fact, we were only able to produce

enough syrup this year for two farmer’s market events at the Mountain Farm & Craft Market.

With this being just our 3rd season at this, we learned something new based on observations of sap flow. After about 3-4 weeks, it

appears that the tap holes in the trees begin to heal up, and taps just about stop flowing, leading to wrong idea that season is over.

Adding another tap to the tree at the point when sap flow from the first tap dramatically decreases, seems to open up the opportunity

for more good flow. Unfortunately, by the time we fully realized this, the temperatures started becoming too warm to continue sap

collection. Next season will require a little more strategy into when we start our first taps, combined with adding a second tap to

the large trees a few weeks later.

In April, I started the long process of building my sugar shack.

Corey's Logs: The 2023 Season

Maple Sugaring Season in North Carolina - Tree Tapping Time

Collecting Maple Sap & Firing Up the Evaporator

Maple Sugaring Season 2023 Ends

Boiling the First Maple Sap of 2023 in the Sugar Shack

Corey's Logs: The 2024 Season

First Maple Sap Boil of 2024

2024 Season Ends

2024 Season Not Over Yet

Getting The Last of The Almost-Syrup Out of the Evaporator Pan